服务热线021-67655331

产品中心

热搜关键词

工频固定式螺杆空压机

产品概况:

※ 【品牌】:格微

※ 【型号】:G-A/W

※ 【功率】:5.5~400 KW

※ 【排气量】:0.52~70m3/min

※ 【排气压力】:0.75~1.30 Mpa

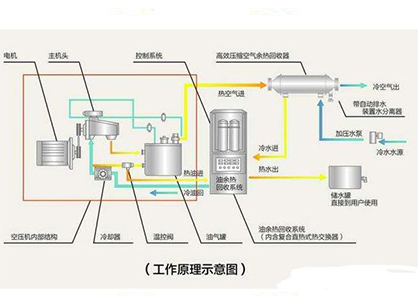

※【简介】:采用德国著名原装品牌主机,无振动,低噪音,大转子,低转速,强大的心脏决定了整机的优异性能。转子经严格的动, 静平衡试验, 使其运转平衡更好, 振动更小, 噪声更低,同时在直径不变的情况下,转子长度增加,有效压缩面积增加,从而达到流量增加,功耗降低。

产品参数:

| G系列螺杆压缩机 G series screw air compressor |

排气压力 Working pressure |

排气量 Capacity |

功率 Power |

噪音 Noise |

空气出口管径 Air outlet pipe diameter |

机组净重 Net weight |

外形尺寸(mm) Dimensions(mm) |

|||||

| bar | psig | (m3/min) | cfm | kW | hp | dB | kg | 长 Length |

宽 Width |

高 Height |

||

| G-5A | 8 | 116 | 0.8 | 29.5 | 5.5 | 7.5 | 60±3 | G3/4″ | 185 | 700 | 690 | 933 |

| 10 | 145 | 0.7 | 24.5 | 5.5 | 7.5 | 60±3 | G3/4″ | 185 | 700 | 690 | 933 | |

| 13 | 189 | 0.5 | 16.1 | 5.5 | 7.5 | 60±3 | G3/4″ | 185 | 700 | 690 | 933 | |

| 16 | 232 | / | / | 5.5 | 7.5 | 60±3 | G3/4″ | 185 | 700 | 690 | 933 | |

| G-7A | 8 | 116 | 1.2 | 43.6 | 7.5 | 10 | 60±3 | G3/4″ | 205 | 700 | 690 | 933 |

| 10 | 145 | 1.0 | 36.9 | 7.5 | 10 | 60±3 | G3/4″ | 205 | 700 | 690 | 933 | |

| 13 | 189 | 0.8 | 26.8 | 7.5 | 10 | 60±3 | G3/4″ | 205 | 700 | 690 | 933 | |

| 16 | 232 | 0.5 | 17.1 | 7.5 | 10 | 60±3 | G3/4″ | 205 | 700 | 690 | 933 | |

| G-11A | 8 | 116 | 1.7 | 60.4 | 11 | 15 | 62±3 | G3/4″ | 225 | 700 | 690 | 933 |

| 10 | 145 | 1.5 | 53.7 | 11 | 15 | 62±3 | G3/4″ | 225 | 700 | 690 | 933 | |

| 13 | 189 | 1.1 | 40.3 | 11 | 15 | 62±3 | G3/4″ | 225 | 700 | 690 | 933 | |

| 16 | 232 | 0.9 | 30.9 | 11 | 15 | 62±3 | G3/4″ | 225 | 700 | 690 | 933 | |

| G-15A | 8 | 116 | 2.4 | 83.9 | 15 | 20 | 62±3 | G11/4″ | 260 | 880 | 820 | 1153 |

| 10 | 145 | 2.1 | 73.8 | 15 | 20 | 62±3 | G11/4″ | 260 | 880 | 820 | 1153 | |

| 13 | 189 | 1.7 | 60.4 | 15 | 20 | 62±3 | G11/4″ | 260 | 880 | 820 | 1153 | |

| 16 | 232 | 1.4 | 50.3 | 15 | 20 | 62±3 | G11/4″ | 260 | 880 | 820 | 1153 | |

| G-18A | 8 | 116 | 2.9 | 100.6 | 18.5 | 25 | 64±3 | G11/4″ | 335 | 880 | 820 | 1153 |

| 10 | 145 | 2.6 | 90.6 | 18.5 | 25 | 64±3 | G11/4″ | 335 | 880 | 820 | 1153 | |

| 13 | 189 | 2.2 | 77.2 | 18.5 | 25 | 64±3 | G11/4″ | 335 | 880 | 820 | 1153 | |

| 16 | 232 | 1.9 | 67.1 | 18.5 | 25 | 64±3 | G11/4″ | 335 | 880 | 820 | 1153 | |

| G-22A | 8 | 116 | 3.7 | 130.8 | 22 | 30 | 64±3 | G11/4″ | 355 | 880 | 820 | 1153 |

| 10 | 145 | 3.1 | 110.7 | 22 | 30 | 64±3 | G11/4″ | 355 | 880 | 820 | 1153 | |

| 13 | 189 | 2.8 | 97.3 | 22 | 30 | 64±3 | G11/4″ | 355 | 880 | 820 | 1153 | |

| 16 | 232 | 2.3 | 80.5 | 22 | 30 | 64±3 | G11/4″ | 355 | 880 | 820 | 1153 | |

| G-30A | 8 | 116 | 5.1 | 181.2 | 30 | 40 | 64±3 | G11/4″ | 700 | 700 | 1105 | 980 |

| 10 | 145 | 4.5 | 157.7 | 30 | 40 | 64±3 | G11/4″ | 700 | 700 | 1105 | 980 | |

| 13 | 189 | 3.9 | 137.6 | 30 | 40 | 64±3 | G11/4″ | 700 | 700 | 1105 | 980 | |

| 16 | 232 | 3.2 | 114.1 | 30 | 40 | 64±3 | G11/4″ | 700 | 700 | 1105 | 980 | |

| G-37A | 8 | 116 | 6.1 | 214.7 | 37 | 50 | 64±3 | G11/4″ | 700 | 700 | 1105 | 980 |

| 10 | 145 | 5.1 | 181.2 | 37 | 50 | 64±3 | G11/4″ | 700 | 700 | 1105 | 980 | |

| 13 | 189 | 4.3 | 151.0 | 37 | 50 | 64±3 | G11/4″ | 700 | 700 | 1105 | 980 | |

| 16 | 232 | 3.8 | 134.2 | 37 | 50 | 64±3 | G11/4″ | 700 | 700 | 1105 | 980 | |

| G-45A | 8 | 116 | 7.986 | 282.02 | 45 | 60 | 65±3 | G1 1/2" | 820 | 1475 | 1060 | 1330 |

| 10 | 145 | 6.732 | 237.74 | 45 | 60 | 65±3 | G1 1/2" | 820 | 1475 | 1060 | 1330 | |

| 13 | 189 | 5.43 | 191.76 | 45 | 60 | 65±3 | G1 1/2" | 820 | 1475 | 1060 | 1330 | |

| G-55A | 8 | 116 | 11.55 | 407.88 | 55 | 75 | 65±3 | G 2″ | 1200 | 1800 | 1170 | 1400 |

| 10 | 145 | 7.876 | 278.14 | 55 | 75 | 65±3 | G 2″ | 1200 | 1800 | 1170 | 1400 | |

| 13 | 189 | 7.689 | 271.53 | 55 | 75 | 65±3 | G 2″ | 1200 | 1800 | 1170 | 1400 | |

| G-75A | 8 | 116 | 13.046 | 460.72 | 75 | 100 | 68±3 | G 2″ | 1750 | 1800 | 1170 | 1400 |

| 10 | 145 | 12.287 | 433.91 | 75 | 100 | 68±3 | G 2″ | 1750 | 1800 | 1170 | 1400 | |

| 13 | 189 | 9.416 | 332.52 | 75 | 100 | 68±3 | G 2″ | 1750 | 1800 | 1170 | 1400 | |

| G-90A | 8 | 116 | 16.489 | 582.30 | 90 | 120 | 68±3 | G2 | 1900 | 2200 | 1400 | 1580 |

| 10 | 145 | 12.947 | 457.22 | 90 | 120 | 68±3 | G2 | 1900 | 2200 | 1400 | 1580 | |

| 13 | 189 | 12.771 | 451.00 | 90 | 120 | 68±3 | G2 | 1900 | 2200 | 1400 | 1580 | |

| G-110A | 8 | 116 | 21.252 | 750.51 | 110 | 150 | 74±3 | G2 1/2 | 2300 | 2200 | 1400 | 1580 |

| 10 | 145 | 16.39 | 578.81 | 110 | 150 | 74±3 | G2 1/2 | 2300 | 2200 | 1400 | 1580 | |

| 13 | 189 | 15.367 | 542.68 | 110 | 150 | 74±3 | G2 1/2 | 2300 | 2200 | 1400 | 1580 | |

| G-132A | 8 | 116 | 23.573 | 832.47 | 132 | 175 | 74±3 | G2 1/2 | 2800 | 2200 | 1400 | 1580 |

| 10 | 145 | 20.95 | 739.84 | 132 | 175 | 74±3 | G2 1/2 | 2800 | 2200 | 1400 | 1580 | |

| 13 | 189 | 16.214 | 572.59 | 132 | 175 | 74±3 | G2 1/2 | 2800 | 2200 | 1400 | 1580 | |

| G-160A | 8 | 116 | 29.975 | 1058.56 | 160 | 215 | 74±3 | DN80 | 3300 | 2650 | 1488 | 1900 |

| 10 | 145 | 23.287 | 822.37 | 160 | 215 | 74±3 | DN80 | 3300 | 2650 | 1488 | 1900 | |

| 13 | 189 | 20.658 | 729.53 | 160 | 215 | 74±3 | DN80 | 3300 | 2650 | 1488 | 1900 | |

| G-185A | 8 | 116 | 32.725 | 1155.67 | 185 | 250 | 74±3 | DN80 | 4000 | 2650 | 1488 | 1900 |

| 10 | 145 | 26.037 | 919.49 | 185 | 250 | 74±3 | DN80 | 4000 | 2650 | 1488 | 1900 | |

| 13 | 189 | 22.836 | 806.45 | 185 | 250 | 74±3 | DN80 | 4000 | 2650 | 1488 | 1900 | |

| G-200A | 8 | 116 | 34.683 | 1224.82 | 200 | 270 | 74±3 | DN80 | 4400 | 2650 | 1488 | 1900 |

| 10 | 145 | 32.604 | 1151.40 | 200 | 270 | 74±3 | DN80 | 4400 | 2650 | 1488 | 1900 | |

| 13 | 189 | 29.15 | 1029.42 | 200 | 270 | 74±3 | DN80 | 4400 | 2650 | 1488 | 1900 | |

| G-250A | 8 | 116 | 44.814 | 1582.59 | 250 | 350 | 78±3 | DN100 | 4700 | 3000 | 1740 | 2100 |

| 10 | 145 | 36.245 | 1279.98 | 250 | 350 | 78±3 | DN100 | 4700 | 3000 | 1740 | 2100 | |

| 13 | 189 | 32.483 | 1147.13 | 250 | 350 | 78±3 | DN100 | 4700 | 3000 | 1740 | 2100 | |

| G-280A | 8 | 116 | 48.52 | 1713.47 | 280 | 400 | 80±3 | DN100 | 4950 | 3000 | 1740 | 2100 |

| 10 | 145 | 44.56 | 1573.62 | 280 | 400 | 80±3 | DN100 | 4950 | 3000 | 1740 | 2100 | |

| 13 | 189 | 36.487 | 1288.53 | 280 | 400 | 80±3 | DN100 | 4950 | 3000 | 1740 | 2100 | |

产品优势

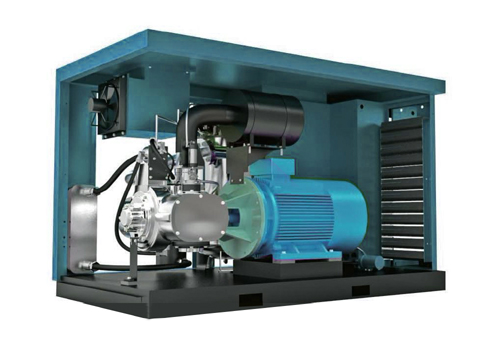

♦G-A型皮带式螺杆空压机

•皮带传动螺杆压缩机在每一种运行阶段均能保持恒定的皮带张力

•卧式布置,箱体机构紧凑,占地面积小

•新型卧式油气分离桶加装特殊档板,压缩空气出口的含油量更低<3ppm

♦G-A型直联式螺杆空压机

•采用1:1直联传动,没有其他噪音,无其他降耗损失,真正意义上的直联式螺杆压缩机,有效的保护电机转矩

•减少传动部件,降低维护成本,提升设备稳定性